Sample analysis gets under way.

This multi-faceted project to de-water farm slurry, recover and precision apply the separated nutrients and organic matter, whilst providing treated water that can be discharged to local water courses without causing undue environmental impacts is under way. For the next few months treatment parameters will be slowly changed during the commissioning phase of the treatment plant in order to determine the best treatment regime. As a starting point, treatment has begun using farm dirty water with a low solid content of ~1% Total Solids. This allows for better understanding of the chemistry involved and provides a yardstick for when increased solids loading is applied. Final solids loading is anticipated to be ~4-5% Total Solids, where the coarse solids in the raw slurry will have already been removed in a screw-press separator prior to treatment. Interestingly, the amount of dissolved solids in the raw slurry is consistently >50% of the % Total Solids – and can rise as high as ~75%. This could lead to an obvious impact on water quality through field run off. If we reduce the dissolved solid content through treatment and apply separated solids at the right time, then field run-off should become less of an issue.

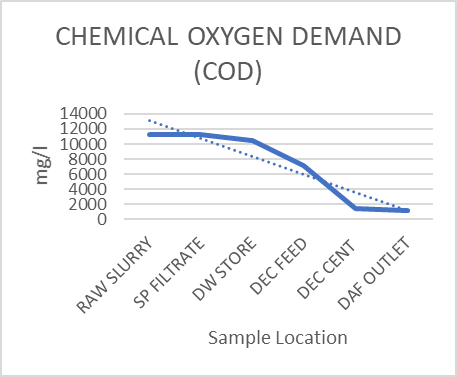

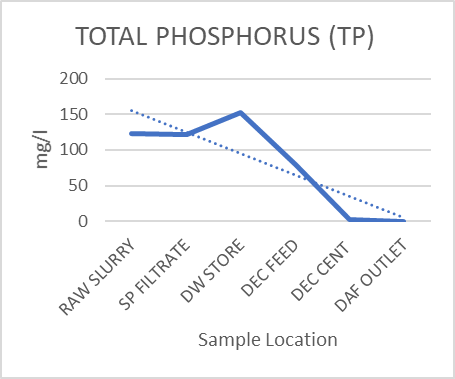

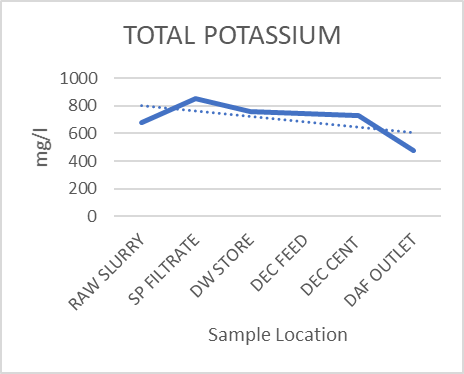

Initial sample analysis results look very promising, with high removal rates seen for most determinands. Predictably, further work however is needed to achieve the goal of reducing concentrations below that of discharge consent. This is expected in time to be achieved at the constructed wetland treatment stage. Currently only potassium removal rates remain relatively low – at 29%. Increasing pH in later trials may allow for improved removal rates for this also.

Currently, the treated water can be re-used on farm for washing equipment and hosing down the milking parlour and yards, saving on clean bore-hole water use. The separated solids are now being generated at apace – ready for field application using precision agriculture equipment next year.

| DETERMINAND | INITIAL % REMOVAL RATES |

| CHEMICAL OXYGEN DEMAND (COD) | 89.33 |

| TOTAL SUSPENDED SOLIDS (TSS) | 96.09 |

| TOTAL NITROGEN (TN) | 68.07 |

| TOTAL PHOSPHORUS (TP) | 99.63 |

| TOTAL POTASSIUM (TK) | 29.33 |

Early indication from laboratory analysis of the separated solids shows that there seems to be no significant difference in macro/micro nutrient and dry matter % content when compared to NRM laboratory benchmarking standards.